Liquid Nitrogen Generators

SCALA - Redefines Liquid Nitrogen Generator

Based on PSA (Pressure Swing Adsorption) N2 generation technology and hybrid Stirling or Gifford- McMahon (GM) cryocoolers pre-installed on top of the dewar tanks, LNS series LN2 generators reduce the footprint, eliminate nitrogen emission, lower energy consumption and improve safety in labs.

· All-in-one Design, Plug-and-play

· Auto Start & Standby

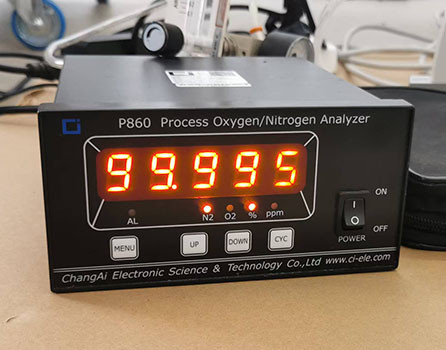

· High-purity 99.95%~99.999%

· loT Function, WiFi & 4G

· 10'' HMI Powered by PLC

SCALA LNS Series Liquid Nitrogen Generators are innovative, plug-and-play solutions designed for laboratories, researching institutions and medical centers. These compact, oil-free air compressor, PSA nitrogen generator, cryo-cooler, and vacuum dewar tank systems provide automated on-site nitrogen production and storage. Controlled by PLC, they generate liquid nitrogen efficiently within hours, with minimal maintenance.

Liquid Nitrogen Components

Featuring with GM and pulse tube cryo-cooler, innovative PSA nitrogen generator, and built-in liquid level gauge, Scala liquid nitrogen generators ensure reliable, long-term performance with low operational costs and easy monitoring. One-click dispensing simplifies usage, with automatic start and standby.

1. Oil-free Air Compressor

Built-in high performance GAST or THOMAS oil-free air compressor, CE & UL certified, complies with global regulations and longer working time.

100% Contaminant-Free Air: Critical for food & beverage, pharmaceuticals, electronics, and medical applications.

Low Noise: Typically reduces noise by 10–30 dB(A), ideal for compliance with workplace noise regulations.

Lower Maintenance: Double cooling fans beside the compressor further extend the service life.

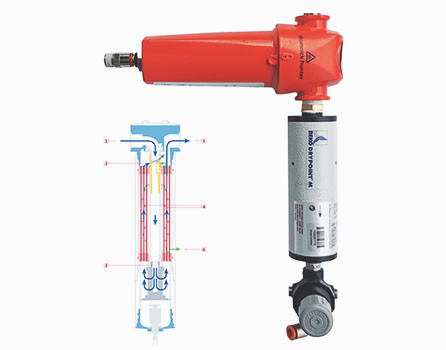

2. PSA Nitrogen Generator

Unlike other brands, Scala liquid nitrogen generators come with PSA nitrogen gas generation system, which means customer do not have to out source nitrogen gas to have independent liquid nitrogen supply.

With high-strength non-welde aluminum adsorption towers with maximum 16 bar-g working pressure, significantly eliminates nitrogen contamination and reducing leakage during liquefication.

3. Large Built-in Dewar

The built-in dewar performs very important role in liquid nitrogen producing. It provides a vacuum insulated room for cryocooler to make ultra-low temperature for nitrogen gas liquefication.

Most LN2 generator manufacturers only provide very small dewar tank to cast costs which cannot meet users' real needs.

Large dewar also means the generator can store more liquid nitrogen for customer applicants. If the dewar is too small it barely can provide enough liquid nitrogen to cool down applicants and perform.

4. Reliable Cryocooler for Nitrogen Liquefication

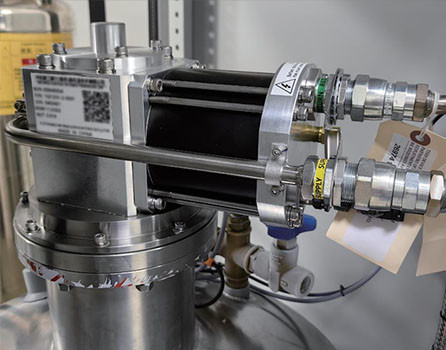

We apply the cutting-edge hybrid Stirling cyrocoolers and GM cryocoolers in scientific researching appliants to make on-site liquid nitrogen generators. With decades of using experience and EU, CE & American UL certification, GM cryocoolers have been proved reliable and safety throughout the world.

Pulse Tube Cryocoolers (PTCs) are advanced, reliable, and efficient systems with unique design, which eliminates moving parts in the cold section, provides significant benefits in terms of durability, low vibration, and noise, making them ideal for sensitive and critical applications.

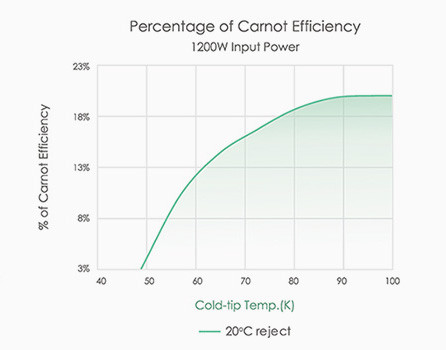

Gifford-McMahon (GM) Cryocooler's high thermodynamic efficiency makes it quickly reaches to the 77K low temperature for nitrogen gas liquefication.

Key Features

When other brands' liquid nitrogen generators rely on manual oversight and guesswork, leading to wasted resources and operational inefficiencies, Scala team has developed cutting-edge products with innovative technologies to delivery unmatched operating experience.

1. Smart Liquid Nitrogen Level Control

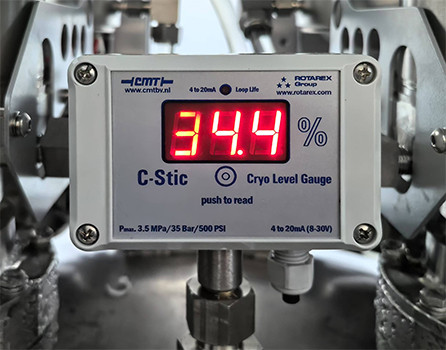

We utilize high sensitive digital level gauge with decades using experience to measure the liquid nitrogen level in the dewar tank, which enables our liquid nirogen generators automatic start & standby according to liquid nitrogen volume pre set.

The settable liquid nitrogen ratio control means you always have enough liquid nitrogen for your applications.

10'' HMI control panel will also display the liquid nitrogen level so you do not have to guess how much liquid nitrogen you have inside the dewar.

2. High Purity Nitrogen 99.95%~99.997%

The high performance CMS (carbon molecular sieves) adsorbent inside the towers, with average diameter 0.9mm, crush strength ≥ 35N and water content 1±0.5%, featuring with high nitrogen production rate, low air-nitrogen ratio and low ash content, make our nitrogen purity easily reach to 99.95%~99.997%.

With built-in nitrogen purity analyzer, users can also read the purity on the HMI.

3. Ultra Clean Liquid Nitrogen

Scala brand liquid nitrogen generators are pre-installed with dust removal filters with removal precision <0.01 μm to make sure only clean nitrogen gas will be liquiefied.

High standard sterilization filters are optional to ensure sterile nitrogen gas before liquiefication for specific field or requirements. The DRYPOINT® M PLUS diffused drying membrane pack with built-in nanoscale filter cartridge provides innovative solution for high standard liquid nitrogen treatment.

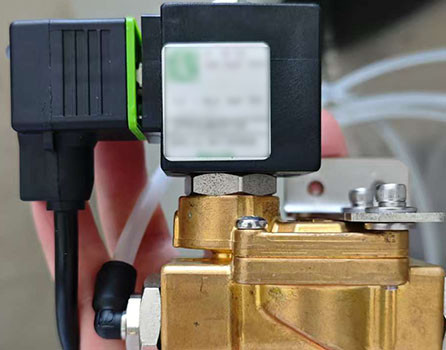

4. Pilot Solenoid Valves

Solenoid valves play important role in controlling the nitrogen gas to be pressured into the dewar tank for liquefication and also in liquid nitrogen dispensing.

The independent four-way solenoid valves increase times efficency to ensure long-term trouble-free operation.

Pilot solenoid valve used for drainage has service life more than 1,000,000 times.

Qualified CE & UL certification, and a switch with a suppressor extends longer service life.

5. Easy Liquid Nitrogen Dispense

When most generators in the market adopts manually dispensing, the globe valve is easily frozen and you have to wait for at least 15 minutes for another dispense.

LNS series comes with cryo solenoid valve dispensing outlet which saves the process of turning off the machine or pressure building process. Press the touch screen and the liquid nitrogen will be dispensed easily and at controllable volume needed.

Dispensing duration is also settable and dispensing stops automatically when time is up (say 300 seconds).

6. Industrial-grade Electrical System

LNS series are powered by Siemens® PLC controller, solid state relays, and world-class electrical components from Schneider®, Weidmüller®, ABB® etc to make sure the reliability of the systems we build.

All models are additionally equipped with physical switches, emergency stops, and buzzer alarms to meet the needs of users in different industries and countries.

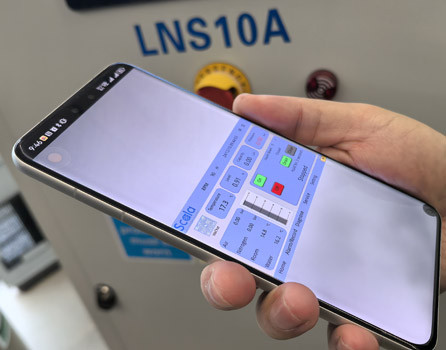

7. Weincloud Monitor for Reliability

Equipped with WeinView® WiFi module, CMT Viewer and EasyAccess 2.0 exclusive remote connection, eliminate firewall or router settings, the liquid nitrogen generators obtain the remote connection service in 5 minutes to do remote monitoring and trouble-shooting any time any where.

You can also choose the most suitable monitoring modeamong cMT Vierwer mobile device monitoring, WebView web monitoring, and VNC Viewer.

8 results

ViewShowcase

LNS20A is a leading liquid nitrogen generator based on advanced GM cryocooler technolog with built-in air compressor, nitrogen generator and dewar tank for LN2 storage.

Innovative all-in-one on site liquid nitrogen generator with built in PSA nitrogen generator, GM cryocooler and 100L vacuum dewar.

This liquid nitrogen generator provides on-site nitrogen generation at 10L/day, ideal for small-scale applications and laboratories needing high purity nitrogen.

A powerful liquid nitrogen generation plant, providing 20L/day output with advanced remote monitoring for large-scale industrial applications.

This compact liquid nitrogen generator with an intuitive HMI touchscreen offers easy control, ideal for laboratory and industrial environments.

Designed for industrial use, this high-purity liquid nitrogen generator delivers 10L/day, ensuring continuous nitrogen production with minimal maintenance.

A small liquid nitrogen generator with a capacity of 8L/day, perfect for labs or research setups with lower nitrogen requirements.

LNS30W is an innovative Liquid Nitrogen Generator designed by SCALA. Integrated with air compressor, nitrogen generator, cryo-cooler and vacuum dewar tank, it can produce high purity liquid nitrogen on-site efficiently and reliably by just one click of the screen.

How SCALA's Liquid Nitrogen Generators Work

Why Choose Scala as Your Liquid Nitrogen Solution

Tailored Solutions

We understand the specific needs of various industries and offer customized, high-purity liquid nitrogen solutions, ensuring your operational efficiency.

Dependable Performance

SCALA’s units are built for reliability, minimizing downtime with automatic, low-maintenance operation, and providing consistent nitrogen supply.

Cost and Space Efficiency

Our compact, plug-and-play systems reduce operational costs and save valuable space, offering maximum productivity in minimal footprint.

Timely Delivery

With our strategically located factory, we ensure prompt and reliable shipments to avoid any delays in your operations.

Other Advantages

- On-Site Production: Plug-and-play, eliminating the need for storing or transporting ensures a continuous and reliable nitrogen supply.

- Installtaion Free and Easy Operation: Compact machinery and totally installation free; One-click start/stop liquid nitrogen generation; One-click to dispense liquid nitrogen automatically.

- Safe and Reliable: No helium compressor or refrigerant compressor means no gas leakage risk.

- Minimal Maintenance: Advanced pluse tube cryo-cooler, over 120,000 hours continuous running without interruption.

- Cost Effective and Environmental: Modern PSA systems minimize energy consumption results in lower operating costs and environmental impact.

- Small Footprint: Easily transported or relocated, portable at different job sites, offering greater flexibility in operations.

- Super Quiet: Built-in low-noise oil-free air compressor, strengthening shock absorption and sound insulation further reduce noise as low as 57dBA @1 meters distance.

What Our Customers Say

Lisa

Medical Assistant

"As a medical service center, we need stable and reliable LN2 supply to support application of our equipment. LNS generator has been one of our most trusted products. It never fails our liquid nitrogen demand. Big thumb up!!"

Tin

Professor

"We have a set of observation apparatus at a remote place which is abusolutely no liquid gas station. Thanks to Scala's on site liquid nitrogen generator we can keep our equipment work at very good conditions."

Michael

Cattleman

"Cryopreservation is crucial to keep our selective breeding of good varieties samples. Before we have co-operation with Scala, we never know there could be such a convevient and reliable liquid nitrogen supply unit. Highly recommend!"

FAQ

Q: What is the lead time of production?

A: Lead time depends on what type you order and your special requirements. Normally we can deliver LNS liquid nitrogen generator in 6-8 weeks after we receive deposit.

Q: Do we need additional equipments to operate LNS series liquid nitrogen generator?

A: No additional equipment is required. LNS series are highly compact units. You just need connect the machine to required power supply and it will generate liquid nitrogen automatically.

Q: What should I do once the liquid nitrogen is produced?

A: LNS series have built-in liquid nitrogen tanks inside the cabinet. Once the liquid nitrogen is generated, it will be storaged in the tanks. Once the liquid nitrogen level reaches the pre-set level in side the tanks, the machine will standby automatically. And once the liquid level is below the pre-set level, the machine will start work and produce liquid nitrogen until it reaches the pre-set level.

Q: How to dispense the liquid nitrogen in the tank?

A: LNS series equiped with both solenoid valve and manually globe valve. When liquid nitrogen is needed, you can dispense the liquid nitrogen to cryopreservation container or self-pressuring tank by click of the HMI screen.

Q: Can we choose specific color of the cabinet door?

A: Absolutely! We understand that choosing the right color is an important decision. Besides, we can provide ODM and OEM and many more customized services.

Q: Do you offer any warranties on your LNS series?

A: Yes, we stand behind the quality of our liquid nitrogen generators and offer warranties on manufacturing defects. If you encounter any issues with your generators due to manufacturing defects, please contact us, and we'll work with you to resolve the issue promptly.