Overview

The most important purpose of compressed air treatment is to remove pollutants and moisture from the compressed air. Condensed water in compressed air systems can corrode, leading to microbial reproduction and long-term harm to industrial production. High humidity of compressed air can lead to failure of air control components, increased wear, or other failures in the production process.

1. High performance requirement:

Dry air pressure dew point requirements vary with different applications. However, these requirements always include that the minimum energy consumption is achieved and that the dried compressed air must be ready for immediate use.

The prerequisite for achieving these requirements is a complete product range of different grades, as well as the manufacturer's accurate grasp of the performance characteristics of the dryer under different working conditions.

2. High Efficiency and Energy Saving:

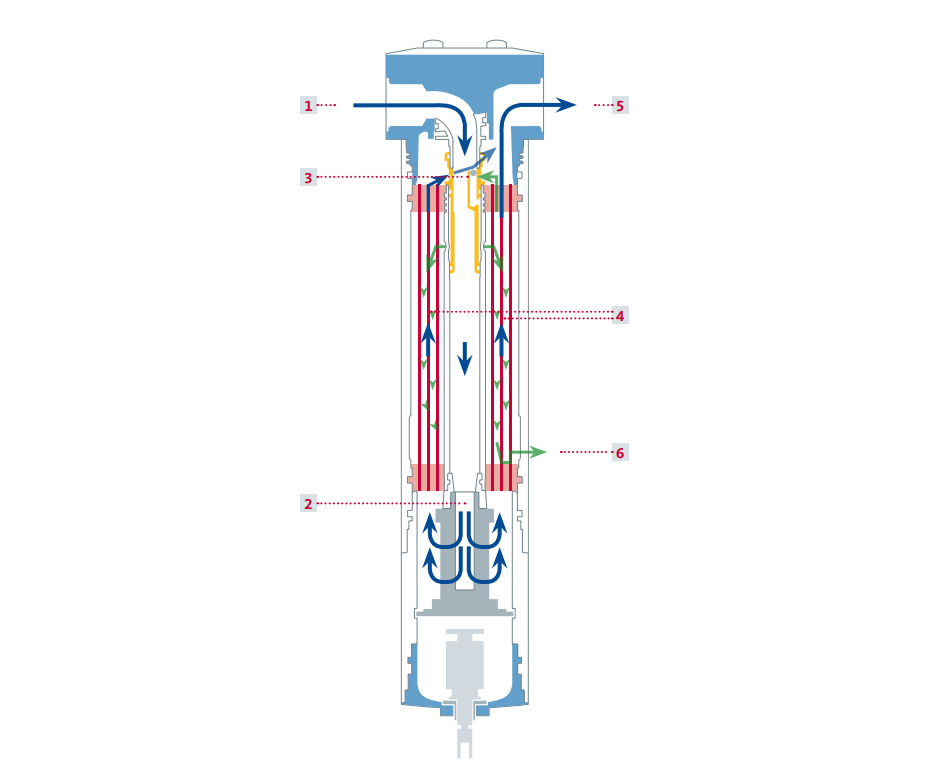

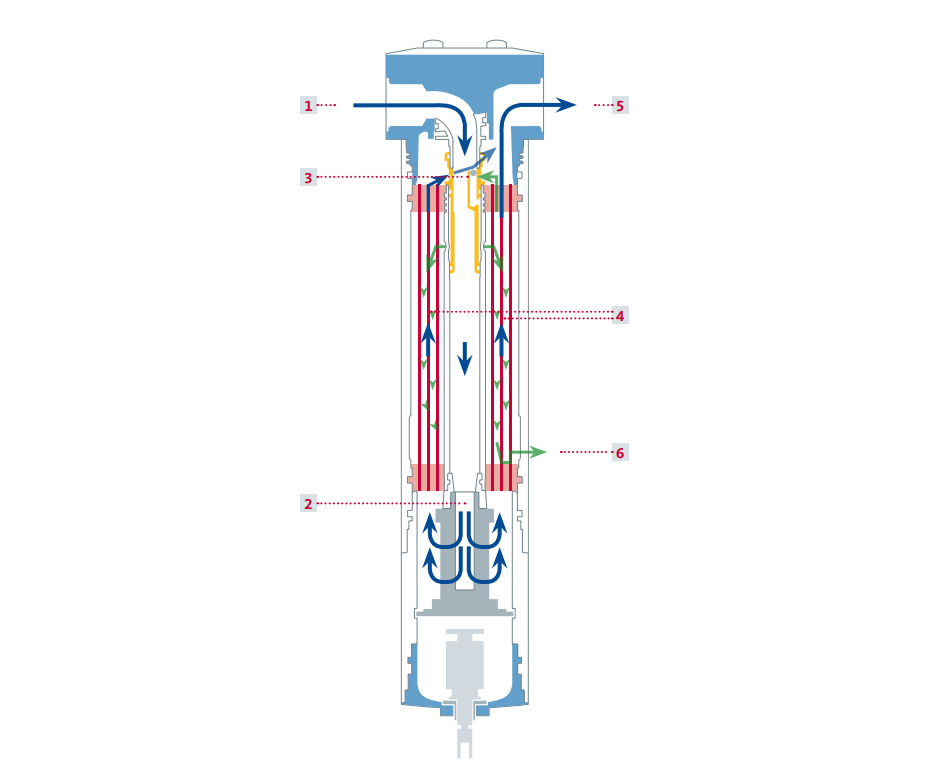

The DRYPOINT® M PLUS diffused drying membrane pack with built-in nanoscale filter cartridge is an innovative solution that integrates filtration and drying in one housing. It requires only a small amount of backblowing to achieve reliable compressed air drying, does not consume electricity, and does not contain desiccant harmful to the environment. The built-in nanoscale filter improves the reliability of the drying film set and compressed air quality, while also increasing the long-term stability of the high permeability hollow fiber tube. The superior properties of DRYPOINT® M PLUS are also suitable for air-breathing drying processes.