Overview

Pulse Tube Cryocoolers (PTCs) are advanced, reliable, and efficient systems with unique design, which eliminates moving parts in the cold section, provides significant benefits in terms of durability, low vibration, and noise, making them ideal for sensitive and critical applications.

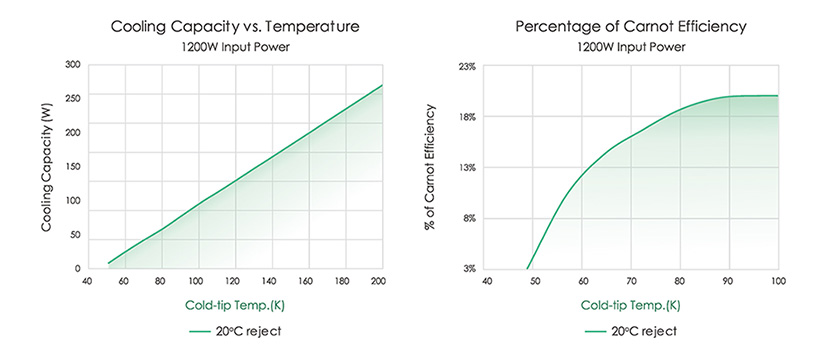

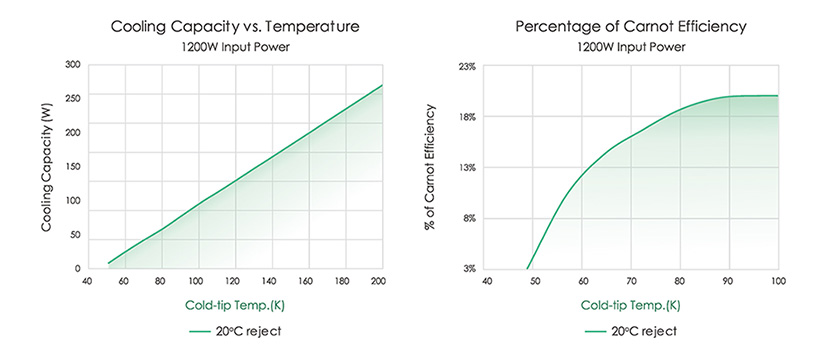

Performance

Pulse Tube Cryocoolers (PTCs) are advanced, reliable, and efficient systems with unique design, which eliminates moving parts in the cold section, provides significant benefits in terms of durability, low vibration, and noise, making them ideal for sensitive and critical applications.

Advantages

1. No Moving Parts in the Cold Section:

Reduced Mechanical Wear: Since PTCs have no moving parts in the cold region, there is minimal mechanical wear, leading to increased system reliability and longevity.

Low Maintenance: The absence of moving parts reduces the need for regular maintenance and repairs, lowering operational costs and downtime. Scala's LN2 generators coolers have an expected over 100,000 hours life span.

2. Low Vibration and Noise:

Suitable for Sensitive Applications: The low vibration and noise levels make PTCs ideal for applications that require a stable environment, such as precision instrumentation, infrared detectors, and scientific experiments.

Environmental Benefits: Reduced noise contributes to a quieter and more comfortable working environment.

3. High Reliability:

Long Service Life: The design's inherent reliability ensures a long service life, making PTCs dependable for critical applications.

Stable Operation: High reliability translates to consistent performance with minimal risk of unexpected failures.

4. High Efficiency:

Energy Efficiency: PTCs are designed to optimize heat exchange and thermodynamic efficiency, resulting in a high coefficient of performance (COP).

Energy Savings: The high efficiency of PTCs helps reduce energy consumption, leading to cost savings and a lower environmental footprint.