Genetic Preservation

Sperm, ova, and embryos from superior breeding animals can be cryogenically stored for extended periods. This enables farmers and breeders to safeguard valuable genetic traits, allowing strategic breeding programs.

Sperm, ova, and embryos from superior breeding animals can be cryogenically stored for extended periods. This enables farmers and breeders to safeguard valuable genetic traits, allowing strategic breeding programs.

The precise temperature control provided by liquid nitrogen tanks is crucial for maintaining the integrity of genetic material during the storage and transport phases of AI and ET processes.

Liquid nitrogen also finds applications in cryosurgery for livestock. This technique involves using extremely low temperatures to remove or treat abnormal tissues, such as tumors or warts.

Maintaining the potency of vaccines is critical in preventing and controlling diseases within livestock populations. Liquid nitrogen serve as reliable storage solutions for vaccines that require ultra-low temperatures.

The use of liquid nitrogen in the cryopreservation of semen contributes to improved semen quality over time. This is particularly beneficial for long-distance transportation of semen from elite breeding animals to enhance genetic diversity within herds.

By preserving genetic material and enhancing reproductive technologies, farmers can strategically plan breeding programs, improve overall herd quality, and optimize the productivity of their livestock operations.

Not every country or region has steady and reliable liquid nitrogen supplier, especially at the vast pasture.

Long distance delivery of liquid nitrogen can be costly and even difficult, and sometimes you only need limited amount.

The ever-changing weather may cause huge problem such as difficult delivery, dramatic changes of LN2 requirement.

Huge loss may cause by irregular LN2 replenishment at busy seasons such as milking, wool cutting new and born wave.

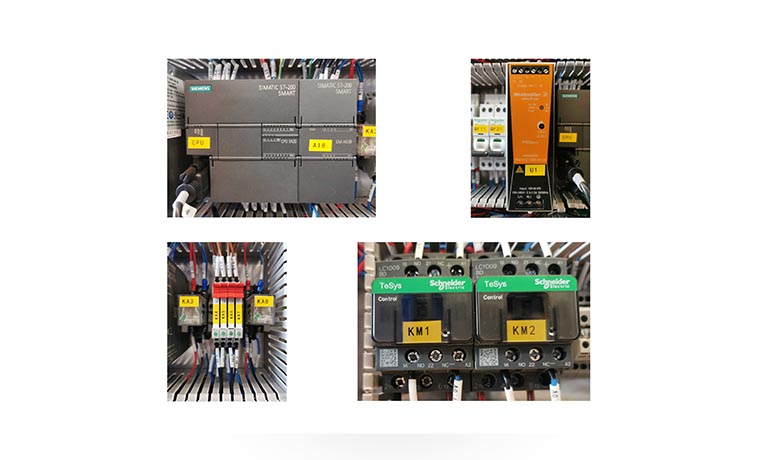

Some liquid nitrogen generators on market are sets of separated machinaries. That means you need to buy a whole range of equipments such as air compressor, nitrogen generator, and dewar tank to support that machine to start liquid nitrogen generation.

Liquid nitrogen generation is not an easy job. The general processes include air compressing, nitrogen generation, nitrogen gas liquification, liquid nitrogen storage and dispensing, and a central processing unit. Most brands on market have tunning high failure rates due to its complex process, let alone to keep the machine work reliably for years.

Most liquid nitrogen generators on market are very hard to operate. It requires complex operations and preparations to start/stop liquid nitrogen generation. Even though you manage to operate, you cannot know what volumn LN2 is generated or left in the dewar tank, and the dispensing process can be annoying and even dangerous.

Your health care center or beauty salon might locate at central down town and the rent is expensive. You do not want a super HUGE generator with loud noise.

Think about maintenance of your liquid nitrogen generator. It might cost you half of the price you bought if you are not using Scala brand. Can you imagine an even worse scenario is the generator needs a depot repair?

Our LNS series liquid nitrogen generators are totally integral units. With built-in air compressor, PSA nitrogen generation system, pulse tube cryocooler, and a large dewar tank, Scala brand LN2 generators can produce liquid nitrogen once linked to electrical power.

Our LNS series liquid nitrogen generators are totally integral units. With built-in air compressor, PSA nitrogen generation system, pulse tube cryocooler, and a large dewar tank, Scala brand LN2 generators can produce liquid nitrogen once linked to electrical power.

LNS series are equipped with 10'' HMI touch screen with super easy operation.

If you want to generate liqiud nitrogen, click On button. That' it!

If you want to dispense liquid nitrogen, click Drain button. Done!

Because we integrate all needed components in one unit, LNS series look like a medium-size refrigerator. Installed with castors, they are easily transported or relocated, portable at different job sites, offering greater flexibility in operations. Noise is as low as 60dBA @1 meter.

We did great effort to lower maintenance frequency and cost.

1. Core component - pluse tube cryocooler, expected running time is over 120,000 hours;

2. All components are replaceable; no depot repair;

3. WiFi connection to do remote diagnose and problem-shooting.

You need only reqular maintenance to keep long time service.

LNS series generators will eliminate the hassle and admin of pre-ordering, scheduling deliveries, and handling tanks. You can produce liquid nitrogen at your office and you will never run out of fresh liquid nitrogen supply.

You will need very high purity nitrogen for the health care. Integrate leading PSA system, LNS series generators produce 99.5%-99.999% high purity nitrogen, and you can acctually read the purity via the HMI screen.

Minimal maintenance frequency, low power comsuption, long time service, reliable supply, with numerous competitive advantages compared to products on market, LNS series can save you tons of money.

LNS series generators are highly intelligent machinaries. They can automatically start or stop producing & storing liquid nitrogen by one touch of the screen. When you need, you can dispense liquid nitrogen by one touch of the screen.

We will work closely with your health care center to customize the liquid nitrogen generator according to your needs, ensuring that it adapts to the liquid nitrogen requirements of the everyday use, from 10 liters/day to 65 liters/day. A customized generator will greatly enhance your business in the market.

As a cryogenics products manufacturer, we will provide professional technical training for the staff of your operator to enable them operate the generator correctly. We will also provide ongoing technical support to ensure the proper maintenance of the equipment and customer satisfaction.