Overview

Programmable Logic Controller, also known as PLC, is a type of industrial computer used to control and automate manufacturing processes, machinery, and other systems. Integrated to modern industrial automation, PLC offers a robust, flexible, and cost-effective solution for industrial automation and control.

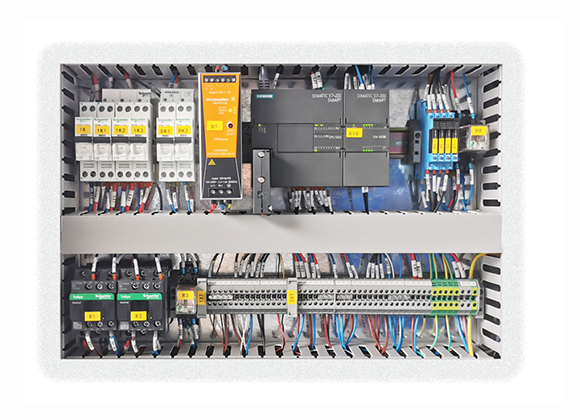

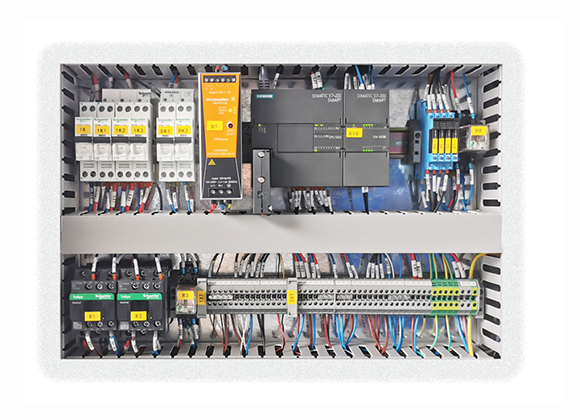

Integrated Siemens CPU, Weidmueller connect power, Schneider contactors and breakers and ABB interface relay, Scala's LNS series liquid nitrogen generators' PLC units exhibite unparalleled advantages than competitive products in operation, LN2 generation, liquid level control, working efficiency and reliability.

Advantages of PLC

1. Reliability and Durability

Robust Design: PLCs are designed to operate in harsh industrial environments, including extreme temperatures, humidity, dust, and electrical noise.

Long Lifespan: PLCs have a long operational lifespan with minimal maintenance requirements, ensuring continuous operation.

2. Real-Time Operation

Immediate Response: PLCs process inputs and outputs in real-time, providing immediate response to changes in the controlled process.

Consistent Performance: Ensures consistent and precise control of industrial processes.

3. Ease of Maintenance and Troubleshooting

Diagnostic Functions: PLCs come with built-in diagnostics and monitoring tools to detect and report faults, simplifying troubleshooting.

Modular Replacement: Faulty modules can be quickly replaced without affecting the entire system, minimizing downtime.

4. Enhanced Safety

Fail-Safe Mechanisms: PLCs can be programmed with fail-safe operations to ensure safety in case of system faults or failures.

Compliance with Safety Standards: Many PLCs are designed to comply with international safety standards, ensuring they meet regulatory requirements.

5. Data Collection and Monitoring

Data Logging: PLCs can log data from the controlled processes, which can be used for analysis, optimization, and predictive maintenance.

Remote Monitoring: PLCs can be accessed and monitored remotely, allowing for real-time oversight and adjustments.

6. Flexibility and Adaptability

Programmability: PLCs can be easily reprogrammed to handle different tasks, making them highly adaptable to changing production needs.

Modular Structure: Many PLCs have a modular design, allowing for easy expansion or reconfiguration by adding or removing modules.

7. Scalability

Suitable for Various Applications: PLCs can be used in small, medium, and large-scale automation systems, from simple control tasks to complex processes.

Expandable: Additional I/O modules and communication interfaces can be added to meet increasing demands.

8. User-Friendly Programming

Standardized Programming Languages: PLCs use standardized programming languages like Ladder Logic, Function Block Diagram (FBD), and Structured Text (ST), which are relatively easy to learn and use.

Simulation and Testing: Many programming environments offer simulation tools to test and debug the control logic before deploying it to the actual system.

9. Interoperability and Communication

Wide Range of Communication Protocols: PLCs support various communication protocols (e.g., Modbus, Ethernet/IP, PROFINET, DeviceNet) to integrate with other devices and systems.

Network Integration: PLCs can be integrated into larger networked systems, enabling centralized monitoring and control.