Overview

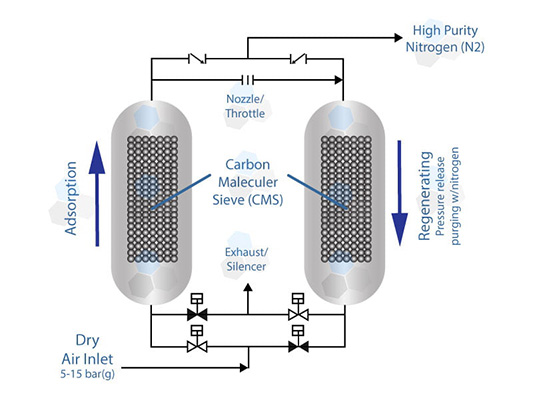

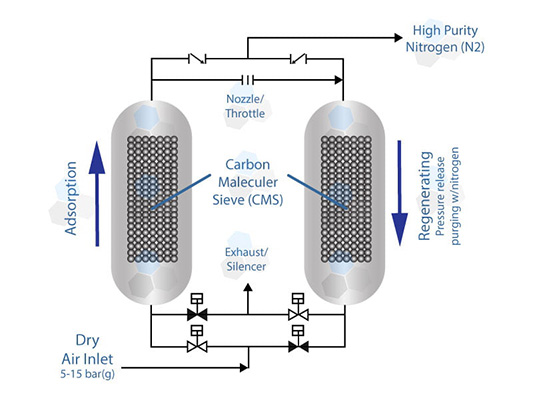

PSA (Pressure Swing Adsorption) Nitrogen Generator is a device used to produce high-purity nitrogen gas from compressed air. It operates based on the principle of pressure swing adsorption, which involves alternating pressure to separate nitrogen from the other gases in the air.

How PSA Cycle Works

The PSA cycle involves coordinated pressure swings in the adsorbent beds to selectively adsorb and desorb gases. There are four main steps:

Feed Pressurization – The bed is brought online and feed air enters, increasing the pressure. Nitrogen passes through while oxygen and argon are adsorbed.

Production – The bed stays pressurized and continues producing nitrogen until the adsorbent nears saturation.

Depressurization – The bed is taken offline and pressure drops, causing adsorbed gases to desorb.

Regeneration – A small amount of product nitrogen purges the bed, prepping it for the next cycle.

Advantages

PSA Nitrogen Generators offer several advantages, making them a popular choice for industries requiring a reliable source of high-purity nitrogen. Here are some key advantages:

· Cost-Effective: PSA nitrogen generators can significantly reduce costs compared to purchasing nitrogen cylinders or liquid nitrogen. On-site generation eliminates transportation, storage, and handling costs.

· Continuous Supply: These generators provide a continuous, on-demand supply of nitrogen, ensuring that operations are not interrupted by the depletion of gas supplies.

· High Purity Levels: PSA technology can produce nitrogen at various purity levels, often up to 99.999%, which can be tailored to specific application requirements.

· Energy Efficiency: PSA systems are generally more energy-efficient than other nitrogen production methods, reducing operational costs over time.

· Low Maintenance: PSA nitrogen generators have relatively low maintenance requirements, especially when compared to other nitrogen production methods. This reduces downtime and maintenance costs.

· Compact and Scalable: These systems are typically compact and can be easily integrated into existing facilities. They are also scalable, allowing businesses to increase nitrogen production as needed.

· Environmental Benefits: On-site nitrogen generation reduces the carbon footprint associated with transporting and storing nitrogen cylinders or liquid nitrogen. This contributes to more sustainable and environmentally friendly operations.

· Safety: Generating nitrogen on-site reduces the risks associated with handling high-pressure cylinders or liquid nitrogen, enhancing overall workplace safety.

· Flexibility: PSA nitrogen generators can be adjusted to produce nitrogen at different purities and flow rates, providing flexibility to meet changing operational needs.